|

|

In 1979, I founded my first company: Dynapro. Marrying my past experience in semiconductor manufacturing (Signetics) with my engineering work on circuit board processing equipment (Morton-Thiokol), Dynapro applied microprocessors to the automation of sophisticated wet metal finishing processes. |

||||||||||

|

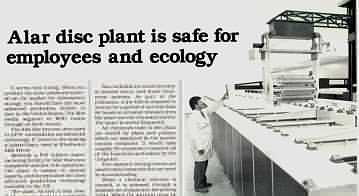

Our technology brought a new level of precision to the automatic monitoring and replenishment of sensitive chemical processes and to the high speed (but gentle) robotic handling of a variety of products. Our initial focus was printed circuit board plating and wafer (semiconductor) fabrication equipment. By 1982 the personal computer industry desperately needed hard disk drives and one of the leading providers of the discs inside hard drives, Ampex, contracted with us to develop the first automatic (electroless nickel/cobalt) disc system ever made. Using multiple Z80 microcomputers in a network, our system monitored and controlled virtually every complex variable in the manufacturing of plated discs. Our first disc system, sold for over $500,000.00 and (shown below) produced about 18,000 discs a day.

Testimonial letters from Dynapro's customers: Hewlett Packard - Parlex - Hallmark - Symtron |

|||||||||||